In industrial production facilities such as chemical, oil and gas, and wastewater treatment plants, knowing and controlling the level of liquids and solutions contained within silos, tanks, barrels, and containers is very important and necessary.

With outdated manual measurement methods that have low accuracy, are difficult to control, incur labor costs, and even pose risks to the safety of workers, Eyesea Technology Joint Stock Company has introduced a solution for measuring, controlling, and remotely monitoring liquids in storage tanks, providing nearly absolute and actionable results. This helps businesses accurately control the liquid levels in their storage tanks. Additionally, it allows for the control of pumps and valves to maintain the liquid at permitted levels and issues alerts in case of incidents.

Classification of Liquid Storage Tanks

Storage tanks are classified in various ways, typically based on their function, size, structure, and the materials used in construction. Below are some common types of storage tanks classified broadly:

Water Tanks

Industrial Water Treatment System (Caption của ảnh bồn chứa nước)

Water tanks are designed to hold water for domestic use, irrigation in agriculture, and livestock, as well as accommodating chemicals or various other liquids. Several materials are used to manufacture water tanks, including polyethylene, stainless steel, concrete, fiberglass, and more. In Vietnam, the most common types of water tanks currently available on the market are stainless steel tanks and plastic tanks. Additionally, some biodegradable water tank products are also increasingly used.

Chemical Storage Tanks

Industrial Chemical Treatment System (Caption của ảnh bồn chứa hoá chất)

Chemical storage tanks are specially designed to hold or mix various chemicals, such as acids, bases, caustic soda, bleach, alum, chlorine, and more. These chemicals typically contain specific chemical components with distinct characteristics, such as high corrosiveness, toxicity, and flammability. Therefore, it is essential to use specially designed storage tanks that meet technical requirements and ensure safety for both humans and the environment.

Fuel Storage Tank

Fuel storage tanks are designed to store liquid fuels such as gasoline, diesel, and other petroleum products. These tanks must be constructed to withstand various environmental conditions and prevent leaks to protect the surrounding environment. Common materials for fuel tanks include steel and fiberglass, chosen for their durability and resistance to corrosion. Proper installation and maintenance of these tanks are essential to ensure safety and compliance with environmental regulations.

Waste Storage Tanks

Waste storage tanks are specially designed to hold waste materials generated from various processes. These wastes often consist of compounds that can precipitate, adhere to surfaces, or have high oxidation potential.

Why Control and Monitor Liquids in Storage Tanks

Theo nguyên lý chung của các bồn chứa chất lỏng: chất lỏng sẽ được lấy từ một nguồn cấp và đưa đến bồn chứa thông qua động cơ bơm. Nếu chỉ hiểu ở mức đơn giản như vậy thì không cần giải pháp để điều khiển hay giám sát nữa rồi.

Issues and Solutions

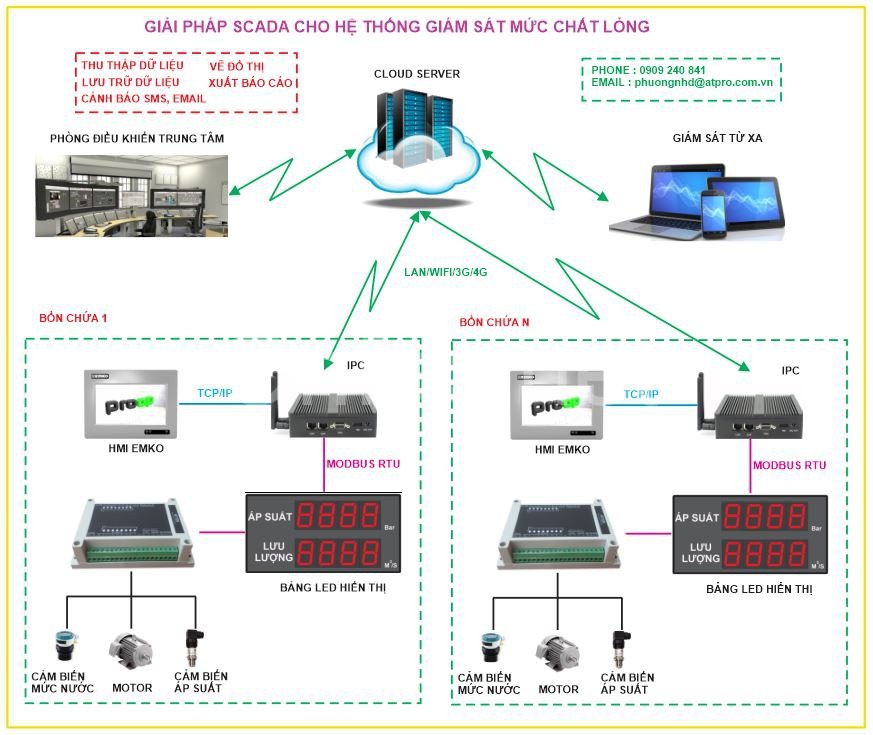

Sensors and pumps will be installed inside the storage tanks to monitor, collect, and transmit data on the pressure and flow of liquids within the tank. This data will be displayed on an LED panel and transmitted to a Cloud Server via LAN/WIFI/4G for storage, processing, and display on software in the central control room. If the liquid level is too high or the pressure is too great, staff in the control room will activate the pump to remove liquid as necessary.

Conversely, when pressure and flow return to normal, the system will notify staff to turn off the pump.

Additionally, the system allows for remote monitoring by sending notifications and alerts to mobile phones via SMS and Email.